Are you interested in setting up a photochromic glass manufacturing plant? Look no further! In this comprehensive guide, I, John Smith, an experienced content writer in the financial industry, will walk you through the process. Discover market trends, understand the manufacturing process, and gain insights into costs and projections. Let's dive in!

Market Overview

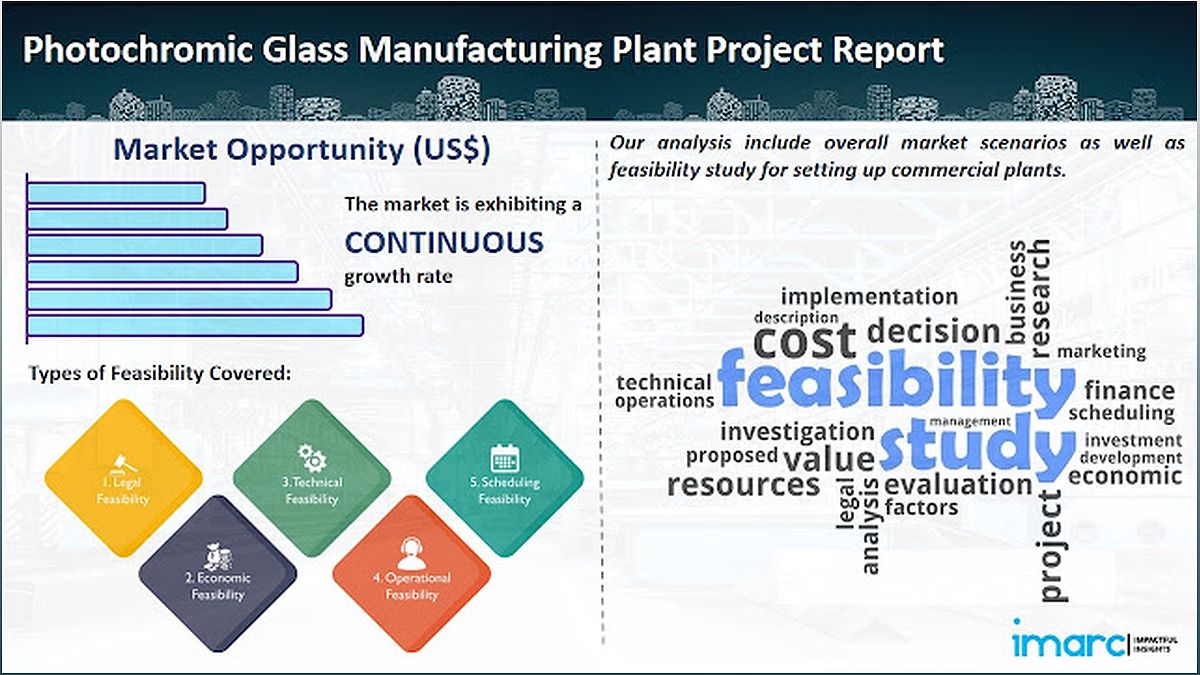

Before diving into the details of setting up a photochromic glass manufacturing plant, let's first understand the market overview. The demand for photochromic glass is on the rise due to increasing consumer awareness of the harmful effects of UV radiation and the growing emphasis on energy efficiency and sustainable design in architecture.

The market is also driven by technological advancements and the integration of photochromic technology in automotive glass. As a result, there is a shift towards eco-friendly and energy-efficient solutions. By establishing a photochromic glass manufacturing plant, you can tap into this growing market and meet the demand for this innovative product.

Photochromic Glass Manufacturing Process

The manufacturing process of photochromic glass involves several steps to ensure the desired quality and functionality of the final product. It typically includes the following:

1. Raw Material Preparation

The process begins with the preparation of raw materials, which include glass substrates, photochromic compounds, and other additives. These materials are carefully selected and processed to meet the required specifications.

2. Coating Application

The next step is the application of a photochromic coating onto the glass substrates. This coating contains the photochromic compounds that are responsible for the tint-changing properties of the glass. It is applied using various techniques such as sputtering, chemical vapor deposition, or spin coating.

3. Curing and Testing

Once the coating is applied, the glass substrates go through a curing process to ensure the proper adhesion and durability of the coating. After curing, the photochromic glass is subjected to rigorous testing to ensure its optical performance, durability, and adherence to quality standards.

4. Cutting, Shaping, and Finishing

The final step involves cutting the photochromic glass into desired sizes and shapes. It may also undergo additional processes such as edge polishing, tempering, and lamination to enhance its functionality and aesthetics.

By following this manufacturing process, you can produce high-quality photochromic glass that meets the market demand.

Infrastructure and Machinery Requirements

Setting up a photochromic glass manufacturing plant requires careful planning and investment in the right infrastructure and machinery. Here are the key requirements:

1. Plant Layout and Space

You need to design an efficient plant layout that allows smooth flow of materials and operations. Sufficient space is required for raw material storage, production area, quality control, packaging, and other essential sections.

2. Machinery and Equipment

Invest in state-of-the-art machinery and equipment that can handle the various stages of the manufacturing process. This includes coating machines, curing ovens, cutting and shaping equipment, testing instruments, and packaging machinery.

3. Utilities and Infrastructure

Ensure a reliable supply of utilities such as electricity, water, and compressed air. Install the necessary infrastructure for waste management, ventilation, and safety measures to create a conducive working environment.

4. Manpower and Training

Recruit skilled personnel who have experience in glass manufacturing or related industries. Provide them with proper training on the manufacturing process, quality control, and safety protocols to ensure smooth operations.

By investing in the right infrastructure and machinery, you can establish a well-equipped photochromic glass manufacturing plant.

Costs and Financial Analysis

Before embarking on any business venture, it is crucial to assess the costs and financial viability. Here's a breakdown of the costs involved in setting up a photochromic glass manufacturing plant:

1. Capital Investment

The capital investment includes the costs of land acquisition, infrastructure development, machinery and equipment purchase, and initial working capital. It is essential to estimate these costs accurately to secure the necessary funding.

2. Operating Expenses

The operating expenses consist of raw material costs, labor costs, utilities, maintenance, packaging, transportation, and other overheads. Proper budgeting and cost management are crucial to ensure profitability.

3. Financial Analysis

Conduct a comprehensive financial analysis to assess the return on investment (ROI), net present value (NPV), profit and loss projections, and break-even point. This analysis will help you make informed decisions and attract potential investors.

By carefully evaluating the costs and conducting a financial analysis, you can determine the feasibility and profitability of your photochromic glass manufacturing plant.

Market Forecasts and Future Opportunities

The photochromic glass industry is poised for significant growth in the coming years. Here are some market forecasts and future opportunities to consider:

1. Market Trends

The market is witnessing a shift towards eco-friendly and energy-efficient solutions. The integration of photochromic technology in automotive glass and the increasing demand for smart windows and eyeglasses are driving the market growth.

2. Emerging Applications

Photochromic glass is finding applications beyond architecture and eyewear. It is being used in various industries such as automotive, aerospace, and healthcare. Exploring these emerging applications can open up new opportunities for your manufacturing plant.

3. Technological Advancements

Stay updated with the latest technological advancements in the photochromic glass industry. Innovations in coating techniques, improved durability, and enhanced optical properties can give your products a competitive edge in the market.

By keeping an eye on market forecasts and future opportunities, you can position your photochromic glass manufacturing plant for long-term success.